|

|

While several advantages of the aerospike have already been indicated, it is important to note those that

contributed to the selection of the aerospike as the primary form of propulsion on the X-33.

Advantages:

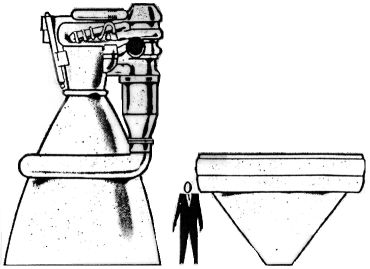

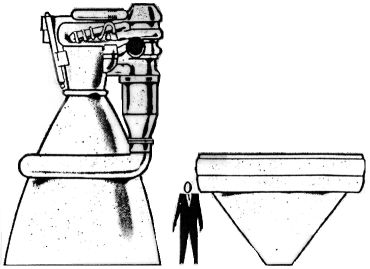

- Smaller nozzle: The truncated spike can be far smaller than a typical bell nozzle for the same

performance, as shown below. In addition, a spike can give greater performance for a given length.

Size comparison of a bell and a plug nozzle [from Berman and Crimp, 1961]

- Superior performance: Altitude compensation may result in

greater installed performance.

- Less risk of failure: The aerospike engine uses a simple gas generator cycle with a lower

chamber pressure than typical rocket engines reducing the risk of a catastrophic explosion.

Although low chamber pressures result in reduced performance, the aerospike's high expansion ratio

makes up for this deficiency.

- Lower vehicle drag: The aerospike nozzle fills the base portion of the vehicle thereby reducing

a type of drag called base drag.

Illustration of aerospike nozzles installed on the X-33 [from Rocketdyne, 1999]

- Modular combustion chambers: The linear aerospike engine

is made up of these small, easier to develop, less expensive thrusters that give the engine

greater versatility.

- Thrust vectoring: Because the combustion chambers can be controlled individually, the vehicle

can be maneuvered using differential thrust vectoring. This eliminates the need for the heavy

gimbals and actuators used to vary the direction of traditional nozzles.

Aerospike thrust vectoring control [from Rocketdyne, 1999]

- Lower vehicle weight: Even though the aerospike tends to be heavier than the bell nozzle, it

shares many major structural elements with the vehicle reducing overall weight.

Disadvantages:

- Cooling: The central spike experiences far greater heat fluxes than does a bell nozzle. This

problem can be addressed by truncating the spike to reduce the exposed area and by passing cold

cryogenically-cooled fuel through the spike. The secondary flow also helps to cool the centerbody.

- Manufacturing: The aerospike is more complex and difficult to manufacture than the bell

nozzle. As a result, it is more costly.

- Flight experience: No aerospike engine has ever flown in a rocket application. As a result,

little flight design experience has been gained.

|