|

||||||||||

|

|

||||||||||

|

||||||||||

|

|

||||||||||

|

|

|

||||||||||||||

|

In discussing the expansion-deflection nozzle, we mentioned that the plug

centerbody forces the exhaust gas flow to remain attached to the nozzle walls increasing the thrust efficiency of

the nozzle. A spike or aerospike utilizes a similar principal except that we want to force the exhaust to remain

attached to the centerbody. Since the aerospike has no outer walls, the pressure of the atmosphere, or the

outer free jet boundary, controls the pressure of the exhaust on the

centerbody. Many believe that this characteristic of aerospike nozzles is their ultimate stength, a concept called

altitude compensation.

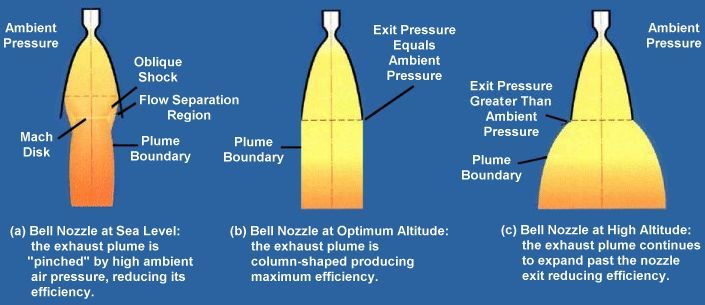

Altitude Compensation:To begin our discussion of altitude compensation, we must first understand how a traditional bell nozzle functions as it operates from sea level to high altitude, as illustrated below.

Bell nozzle behavior during flight [from Rocketdyne, 1999]As discussed in the above figure, bell nozzles suffer from reduced efficiency at low and high altitude because of the difference between the pressure of the exhaust gases and the ambient pressure of the atmosphere. At low altitudes, the exhaust pressure is too low, and the higher atmospheric pressure pushes the exhaust inward. This inequality causes the exhaust to become separated from the nozzle walls reducing the amount of thrust generated. This condition is known as overexpansion. At high altitude, the bell nozzle suffers from the reverse problem. Here, the exhaust pressure is much higher than the ambient pressure causing the exhaust to continue to expand past the nozzle exit. Since the additional expansion occurs outside of the nozzle, that expansion does not exert thrust on the nozzle, so that thrust is lost. This condition is known as underexpansion. At the optimum altitude, for which the nozzle is tailored during the design process, the exit pressure equals the ambient pressure. Note in the above figure that the exhaust plume becomes column shaped indicating that the exhaust is perfectly expanded thereby maximizing efficiency and thrust. Thus, both overexpansion and underexpansion reduce overall engine efficiency and thrust. If we could somehow minimize the exit area at launch and increase it as the rocket ascends, we could optimize the nozzle for each altitude and maximize the thrust. Such a nozzle, would markedly improve overall performance. An ideal nozzle would be able to continually adjust its contour, area ratio, and length to maximize thrust at each altitude (see the figure below), a concept known as altitude compensation.

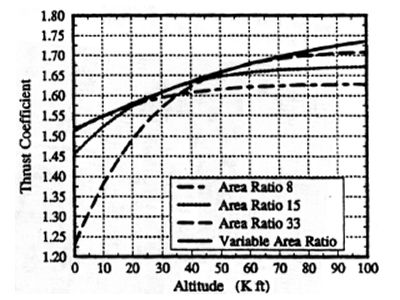

Ideal nozzle that continually adjusts its geometry as altitude increases [from Rocketdyne, 1999]However, a bell nozzle that continually changes its geometry is clearly not practical, and the designer must instead make a series of tradeoffs in selecting the area ratio of a nozzle. The following graph gives some idea of the issues the designer must consider.

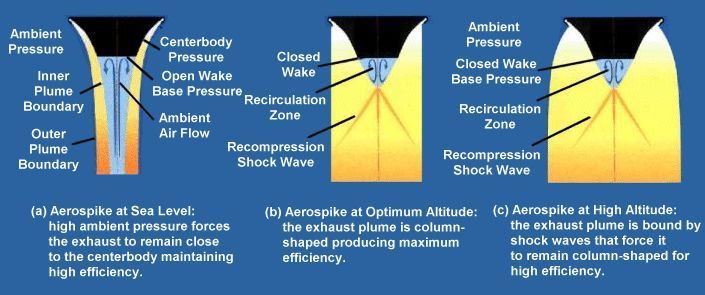

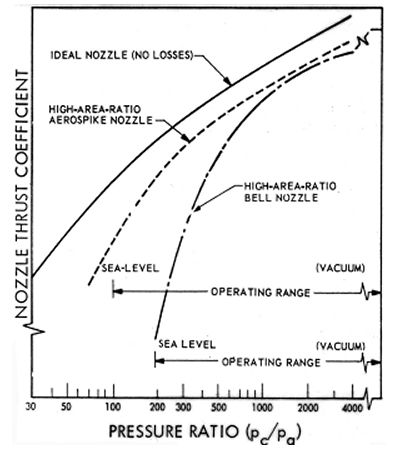

Ideal thrust coefficient for fixed area ratio and continously variable area ratio nozzles [from Ruf and McConnaughey, 1997]The ideal nozzle, indicated by the thick solid line, represents the maximum performance possible. At low altitudes, we want a small area ratio, meaning the exit area is small, to minimize overexpansion. However, the graph shows that we will pay for this excellent performance at low altitude with underexpansion at high altitude resulting in large thrust losses. The converse is true of a high area ratio--high altitude performance is maximized at the expense of overexpansion and poor efficiency at low altitude. While altitude compensation is certainly desirable in any rocket application, this adaptive quality is a virtual necessity in any Single Stage to Orbit (SSTO) vehicle, like the X-33. Some believe that a reasonably sized payload simply cannot be carried from sea-level to orbit in a one-staged vehicle with current engine technology. Numerous methods of incorporating altitude compensation have been tried. Examples include extendible nozzles that "grow" through flight, "aspirated" nozzles in which ram air is injected into the nozzle to fill the exit and keep flow attached, and a step along the nozzle wall that prevents the flow from overexpanding at low altitude. However, many claim that the ultimate strength of the aerospike nozzle is its inherent altitude compensation capability, as shown below.

Aerospike nozzle behavior during flight [from Rocketdyne, 1999]This ideal behavior results from the fact that the outer plume boundary of the primary flow is acted upon only by the ambient pressure of the atmosphere. Recall from our discussion of aerospike thrust characteristics, high ambient pressure at low altitudes forces the exhaust inward increasing the pressure on the "centerbody" and the centerbody component of thrust. In addition, the base region is open to high ambient pressure resulting in a greater "base" thrust component. At design pressure, the flow becomes column shaped, much like a bell nozzle, for maximum efficiency. When operating at low ambient pressure (at high altitude or in a vacuum), the flow is constrained by expansion/compression waves that direct the exhaust axially to maintain the thrust force on the centerbody. At low pressures, however, the nozzle operates in a "closed wake" state. Since the base is not subject to a high ambient pressure, there is no altitude compensation benefit, and the aerospike behaves like a high area ratio bell nozzle. Thus, in theory at least, the aerospike nozzle meets or exceeds the performance of the bell nozzle at all operating pressures.

Comparison of theoretical nozzle performance [from Huzel and Huang, 1967]

|

|

Aircraft | Design | Ask Us | Shop | Search |

|

|

| About Us | Contact Us | Copyright © 1997-2023 | |||

|

|

|||