|

||||||||||

|

|

||||||||||

|

||||||||||

|

|

||||||||||

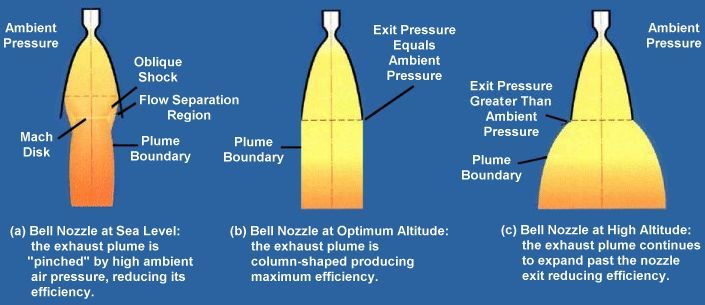

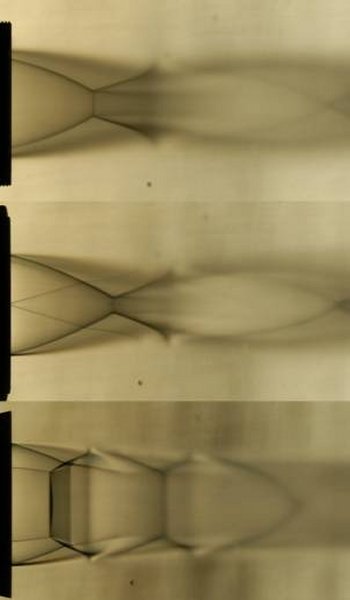

The behavior of this expansion process is largely dictated by pressure--both the pressure of the exhaust itself as well as the pressure of the external environment into which it exhausts. Of greatest concern is to design the shape and length of the nozzle so that it converts as much of that thermal energy into thrust as possible. In an ideal nozzle that optimizes performance, the exit pressure (Pexit) will be equal to the ambient pressure of the external atmosphere (P¥). The flow in this case is perfectly expanded inside the nozzle and maximizes thrust.

Unfortunately, this situation can only occur at one specific atmospheric pressure on a fixed-geometry nozzle. As we have seen previously, pressure decreases as altitude increases. Nozzle designers typically must select a shape that is optimum at only one altitude but minimizes the losses that occur at lower or higher altitudes. These losses result from the fact that the atmospheric pressure will either be higher than the exit pressure of the exhaust gases, i.e. at low altitudes, or lower than the exit pressure, i.e. at high altitudes.

This first case, where the external pressure is higher than the exit pressure, is referred to as overexpanded. When an overexpanded flow passes through a nozzle, the higher atmospheric pressure causes it to squeeze back inward and separate from the walls of the nozzle. This "pinching" of the flow reduces efficiency because that extra nozzle wall is wasted and does nothing to generate any additional thrust. Ideally, the nozzle should have been shorter to eliminate this unnecessary wall.

The opposite situation, in which the atmospheric pressure is lower than the exit pressure, is called underexpanded. In this case, the flow continues to expand outward after it has exited the nozzle. This behavior also reduces efficiency because that external expansion does not exert any force on the nozzle wall. This energy can therefore not be converted into thrust and is lost. Ideally, the nozzle should have been longer to capture this expansion and convert it into thrust.

I can understand your point that flipping the names would seem more intuitive since I too found definitions of overexpanded and underexpanded flows to be confusing when I first learned them. For example, it seems logical to conclude that the flow in the high altitude case "over expands" the diameter of the nozzle after it exits, hence its larger size.

However, the proper definitions make more sense if you think about them from the perspective of the nozzle exit. A flow is always being asked to expand outward to the diameter of the nozzle exit in order to maximize thrust. At low altitude, however, this expansion requires more energy than the flow possess because of the higher external pressure. As it tries to do so, the flow "over expands" itself and is forced back inward by that higher pressure. The opposite is true at high altitude where the flow has too much energy. By the time it reaches the nozzle exit, the flow has "under expanded" itself in comparison to what it is capable of.

Additional information about nozzles and the importance of flow expansion is available in the

Aerospaceweb.org site about the

aerospike engine. This site presents a more in-depth discussion about nozzle

design as well as the advantages and disadvantages of different types of nozzle shapes.

- answer by Jeff Scott, 20 March 2005

Related Topics:

Read More Articles:

|

Aircraft | Design | Ask Us | Shop | Search |

|

|

| About Us | Contact Us | Copyright © 1997-2023 | |||

|

|

|||