|

||||||||||

|

|

||||||||||

|

||||||||||

|

|

||||||||||

|

|

|

|||||||||||||

|

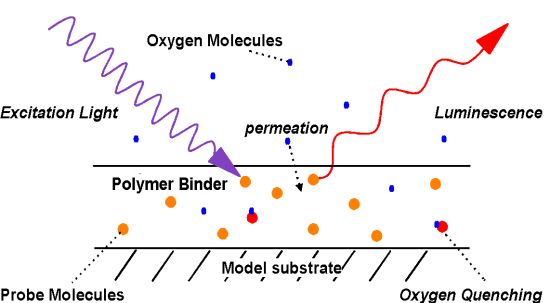

Characteristics of PSP:As mentioned previously, PSP simply consists of a luminescent molecule suspended in some type of oxygen permeable binder. Currently, the majority of these binders are some form of silicone polymer. The vast majority of PSP formulations to date come in a liquid form that is suitable for use with normal spray-painting equipment and methods.

PSP excitation and luminesenceTypically, in its simplest application, PSP is the topmost layer of a multilayer coating on a model surface. The PSP is usually applied over a white undercoat, which provides two related benefits. The white undercoating reflects a large portion of the light that is incident upon it, which results in the benefits of amplifying not only the excitation illumination, but the emission illumination as well. Advantages:As previously mentioned, pressure sensitive paints are used to measure surface pressures. The conventional methods of measuring these pressures is to apply pressure taps or transducers to a model, but these approaches have some significant disadvantages. First of all, taps and transducers only allow measurements at discrete points on the model surface. The surface pressures at other locations on the model can only be interpolated from the known points. Another disadvantage is that taps and transducers are intrusive to the flow. Measurements cannot be taken downstream of other taps or transducers, since the flow is altered once it passes over the upstream disturbances. Finally, taps and transducers are time-consuming and expensive to use. Typical models used for determining surface loads in aircraft design typically cost $500,000 to $1 million, with approximately 30% of that cost going towards the pressure taps and their installation. A relatively new method to surface pressure measurement utilizes pressure sensitive paint, or PSP. Pressure sensitive paint has numerous advantages over the more conventional pressure taps and transducers. The most obvious is that PSP is a field measurement, allowing for a surface pressure determination over the entire model, not just at discrete points. Hence, PSP provides a much greater spatial resolution than pressure taps, and disturbances in the flow are immediately observable. PSP also has the advantage of being a non-intrusive technique. Use of PSP, for the most part, does not affect the flow around the model, allowing its use over the entire model surface. The use of PSP eliminates the need for a large number of pressure taps, which leads to more than one benefit. Since pressure taps do not need to be installed, models can be constructed in less time, and with less money than before. Also, since holes do not need to be drilled in the model for the installation of taps, the model strength is increased, and higher Reynolds numbers can be obtained. Not only does the PSP method reduce the cost of the model construction, but it also reduces the cost of the instrumentation needed for data collection. In addition, the equipment needed for PSP costs less than pressure taps, but it can also be easily reused for numerous models. In aircraft design, PSP has the potential to save both time and money. The continuous data distribution on the model provided by PSP can easily be integrated over specific components, which can provide detailed surface loads. Since a model for use with the PSP technique is faster to construct, this allows for load data to be known much earlier in the design process.

Disadvantages:Unfortunately, PSP is not without its undesirable characteristics. One of these characteristics is that the response of the luminescent molecules in the PSP coating degrades with time of exposure to the excitation illumination. This degradation occurs because of a photochemical reaction that occurs when the molecules are excited. Eventually, this degradation of the molecules determines the useful life of the PSP coating. This characteristic becomes more important for larger models, as the cost and time of PSP reapplication becomes a significant factor. A second undesirable characteristic of PSP is that the emission intensity is affected by the local temperature. This behavior is due to the effect temperature has on the energy state of the luminescent molecules, and the oxygen permeability of the binder. This temperature dependence becomes even more significant in compressible flow tests, where the recovery temperature over the model surface is not uniform. |

|

Aircraft | Design | Ask Us | Shop | Search |

|

|

| About Us | Contact Us | Copyright © 1997-2023 | |||

|

|

|||